There are as many ways to describe materials science as there are materials scientists. The most basic definition of the field is this: Materials science and engineering is the interdisciplinary study of useful matter (see how I avoided just reusing “materials?”). Since the field is so broad, it’s difficult to provide a more precise definition than this. However, we can make many other generalizations.

Materials science is a unique combination of science and engineering, physics and chemistry, logic and creativity. I have a separate article explaining why we use both “science” AND “engineering” when discussing our field, but for the sake of convenience, I’ll use “materials science” and “materials engineering” interchangeably. Most of the time, professionals and students in the field prefer simply “materials science” because it’s faster to say and type.

Outline

- The Simplest Definition: Materials Science = Physics x Chemistry

- Philosophy of Materials Science: The Materials Tetrahedron

- My Favorite Definition: Engineering Across Length Scales

- How does Materials Science fit with other STEM Fields?

- But What Do Materials Scientists Actually Study?

- Branches of Materials Science

- Fundamental Concepts

- What is the Difference Between Materials Engineers and other Engineers?

- Jobs in Materials Science

- Final Thoughts

The Simplest Definition: Materials Science = Physics x Chemistry

One of the most common descriptions of materials science is the intersection of physics and chemistry.

The Venn diagram above can give you a quick idea about what topics are shared between physics and chemistry and how that plays into materials science. But even this is only part of the story. Many chemistry ideas that don’t have anything to do with physics can fall under the purview of materials science, and vice versa. For example, “food science” is a topic that you would think falls under the umbrella of chemistry. Yet I know materials scientists who have studied chocolate and ice cream. I know other materials scientists who work with nuclear physicists to develop radiation-resistant materials.

Materials science can also integrate with biology, mechanical engineering, and other fields. One of my undergraduate projects dealt with bioactive prosthetic implants (we tried to coat the surface material with a glass that would “trick” your body into thinking it was bone), and one of my graduate colleagues used computational modeling to predict materials and was hired to write trading algorithms for a stock brokerage.

Philosophy of Materials Science: The Materials Tetrahedron

Rather than defining materials science by the kinds of science involved, I think it’s more accurate to define the field by its philosophy. I cover the pedagogy of materials science more in my article about the history of materials science and engineering, but if a core principle of materials science exists, it is the materials tetrahedron.

The tetrahedron has 4 points–processing, structure, properties, and performance. Sometimes you may see “characterization” in the center (characterization is how you measure each of those points). I have an entire article dedicated to explaining the materials tetrahedron, but in short:

- Performance is how good a material is. Can it be used as landing gear? How about as an insulator? A material’s performance is tied to a combination of separate properties.

- Properties are macroscopic things about a material that you can measure–hardness, elasticity, thermal conductivity, electrical conductivity, density, coefficient of friction, etc. Properties are determined by a material’s structure.

- Structure is the feature of a material operating on different length scales. Structures can be large enough to see with the naked eye, or as small as atomic spacing. Some examples of structures include pores, precipitates, grain boundaries, grain orientation, and crystal structure. Structure is often influenced by processing.

- Processing refers to the steps needed to create a material. This often means the final steps to create a material–for example, heat treating and quenching to influence grain size–but it can even include mining raw ore and converting it into a more useful state.

All 4 of these points interact, which is why the tool is typically visualized as a tetrahedron, with edges connecting each side. As you may have noticed during my explanation, however, some sides interact more than others. One alternative to the materials tetrahedron, which presents the 4 points in a linear order and is championed by professor Greg Olson, is shown below.

In most cases, we think about processing insofar as it affects structure; we think of structure to fine-tune our desired properties, and we think of ideal properties to fit some performance in a specific application. Personally, however, I still prefer the original tetrahedron with all sides connected. For example, if you can process a material more cheaply, you can increase the performance metric of “price” while leaving the structure and properties alone. Or perhaps you may change the structure with the goal of making processing easier, rather than increasing performance.

My Favorite Definition: Engineering Across Length Scales

The materials tetrahedron ties into my favorite definition of materials science, which I first heard from my undergraduate research advisor. He liked to say that materials science was “engineering across length scales.” I think that idea captures the soul of materials science. Unfortunately, while it makes perfect sense to someone already in the field, it’s a bit difficult to explain to a layperson. Take an example, and don’t worry if you don’t understand all the terms and concepts–if you’re interested in learning more, this site can explain everything you need to know.

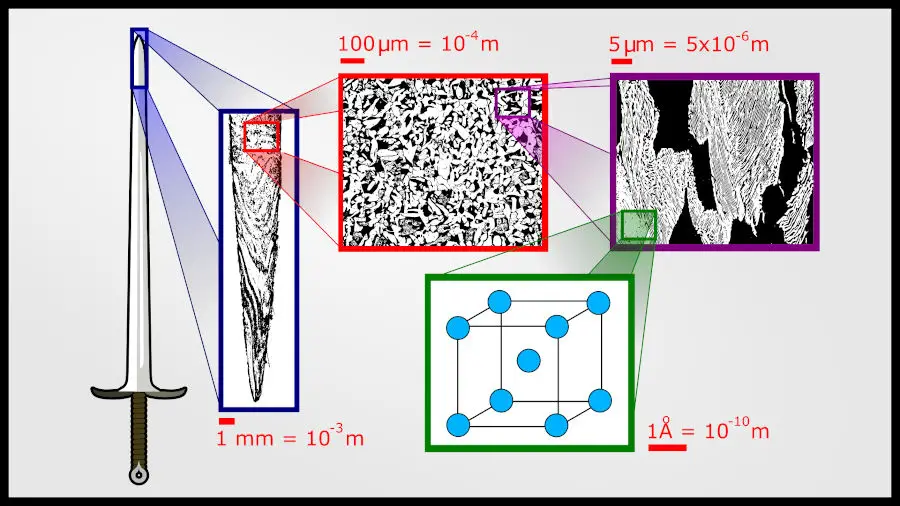

Imagine a sword (yes, materials scientists like swords so much that the biggest annual materials science conference has a student bladesmithing competition). You can definitely read more pages on this site for cool details, but as an introduction, a sword is made of steel. If you look deeper, you’ll find that this steel is mostly iron, but parts of the steel are made of cementite Fe3C or other precipitates. Looking even deeper, you’ll see that the iron and cementite are arranged in “grains,” or clusters of atoms all arranged in the same direction. We can distinguish grains because the atoms like to arrange in a repeating structure. We call this a “crystal” and the exact crystal structure has to do with quantum behavior of the protons, neutrons, and electrons.

This is what I mean by length scales. Are you modeling atoms or bulk material? Grains or precipitates? The atoms influence the crystal structure–so materials scientists can use different elements to adjust the material’s composition. The crystal structure–and thermodynamics and kinetics involved in heat treatment–can affect the grains. The grains can affect precipitates, and together they make the sword strong, hard, and tough. A materials scientist makes a change on one length scale to achieve a change on a different length scale.

Physicists tend to concern themselves with subatomic length scales (like quarks or muons), and while there’s no reason materials science principles couldn’t continue scaling up indefinitely, we tend to confine our focus. Once we have something made of many disparate materials (like a building), we conscript an architect or civil engineer. Geologists examine objects on a planetary scale, and astrophysicists theorize the nature of the universe. You will see materials scientists working on all of these projects, but that is the nature of the field. We blend so seamlessly into other disciplines–not just chemistry and physics–that it is impossible to precisely define what “belongs” to materials science. Everything is made of materials, and so materials scientists have a “claim” to work on any branch of science.

Look at any university and you will see that materials science has the highest percent of join-department faculty. It’s not unheard-of for a professor to be given honorary membership in the mechanical, physics, and chemistry departments.

How does Materials Science fit with other STEM Fields?

It’s also important to discuss what materials science is within the context of modern STEM fields. Materials science, while critical for modern technological advancement, is not well known.

One of the goals of this site is to increase society’s familiarity with materials science–the more people understand and study this field, the sooner we will see technological advancement. Many awards are attributed to physics or chemistry when they in fact deal with materials science. For instance, since 2010, 5 Nobel prizes in Physics or Chemistry were awarded for materials science topics.

Along with medicine, materials science is one of the fields undergoing the most rapid development.

Because the field is so new, materials science is the bottleneck of modern engineering. Think about what limits us from any technological breakthrough? Why do internal combustion (i.e. regular, non-electric) cars have such low energy efficiency? It’s not because we are bad at building engines, it’s because we purposefully waste fuel to avoid melting the material the engine is made of!

The other workaround to increase car efficiency–switching to electric–also relies on advancement in materials science, especially batteries. Smartphones didn’t exist 10 years ago–not because nobody thought of them, but because we didn’t have sufficient materials to make touchscreens, batteries, or processors. Moore’s law predicts that computational power doubles every two years–materials science makes this possible by creating ever purer silicon wafers. Even the physics involved as we shrink transistors far enough to feel quantum effects are the kinds of physics studied most by materials scientists.

Look at nearly all useful engineering breakthroughs in the last two decades, and you will see that it was made possible by advances in biological understanding, computational power (assisted by materials science), or materials science.

But What Do Materials Scientists Actually Study?

Well, materials. Duh.

In general, there are 4 types of materials: metals, ceramics, polymers, and composites. Materials scientists apply the materials tetrahedron discussed above, but the actual subject is a material, and nearly all materials fall into one of these categories.

- Metals are characterized by metallic bonding, and can easily be distinguished by their placement on the periodic table. With some exceptions, most engineering metals are primarily composed of a single (metallic) element. Because of metallic bonding, metals are shiny, ductile, and conduct electricity.

- Ceramics are characterized by ionic or covalent bonding. This bonding is directional and results in ceramics being very brittle. Ceramics are usually a stoichiometric combination of two nonmetals (covalently bonded, like diamond), or a metal and a nonmetal (ionically bonded, like salt).

- Polymers are strings of molecules attached together. These chains are stuck together by van der Waals or London dispersion forces. Each unit of the chain is called “mer” and thus polymer means “many mers.” Polymers usually rely on carbon chains to form the repeating mer units. Plastics are the most common type of polymer, although most biological matter may also be classified as a polymer (or better yet, a polymer composite, like wood).

- Composites are a mixture of different materials, arranged in a macro-scale structure to give the best combination of properties. For example, most concrete is a composite between cement (as glue), gravel (for compressive strength and cost reduction), and steel rebar (for tensile strength). Foam would be a composite of the base material and air, and wood is a naturally occurring polymer composite.

You’ll notice that each of these 4 categories are solids. That’s because you can’t build with liquids or gases. They are very useful in materials science, but the final product is rarely in liquid or gas form. Actually, these 4 classifications still apply to fluids. For example, water and carbon dioxide are both ceramics, which can be easy to tell by examining their solid form. Nearly all materials that are fluid at room temperature are bonded covalently, and thus can technically be described as a ceramic.

Sometimes, the same material can have many different functions, so we often split materials science into branches based on the material’s intended application.

Branches of Materials Science

Categorizing material applications into branches is more philosophy than science. For instance, my wife Ewelina likes to categorize all of materials science into just 2 branches: Structural Materials and Functional Materials. Other people may choose categorizations that overlap more significantly. Below I will list a few of the most common branches, explain which materials fit into which branch, and where branches overlap. Remember, branches are chosen based on the material’s intended application. For example, copper may be an energy material when you are looking at its conductive properties, but it may be a structural material when you are looking at its mechanical properties.

Structural materials are materials which are designed to maximize mechanical properties. Mechanical properties include strength, flexibility, hardness, toughness, etc. Mechanical properties are a small subset of all possible properties, but since everything we build needs to support some load, mechanical properties get their own special category. A materials scientist working on structural materials is most likely to prefer to be called an “engineer.” Engineers working on aerospace materials, metallurgy, or ceramics are likely to consider their materials to be “structural.”

Functional materials are materials which display some “unique” properties. These are properties that some materials have, and others don’t. All materials share some common properties–for example, strength or conductivity. Everything has some degree of strength–even if you were to quantify the strength of a gas as “zero,” you would still be acknowledging that it has a place on the spectrum. On the other hand, most materials don’t have the properties possessed by functional materials. Examples of these properties include ferromagnetism (or as the layperson would say, magnetism), piezoelectricity, thermoelectricity, and even some properties so rare they don’t have names (such as the collective group of “smart” materials)! As you can see with the image below, we don’t say a non-ferromagnetic material has zero magnetism. It simply doesn’t have the property.

Electronic, Magnetic, and Optical materials can sometimes be included as part of functional materials, but if an institution has a large research focus on one of these areas, it will probably get its own division. Electronic materials deal with changing the way electrons flow through the material (or materials that are important to other electronic materials), Magnetic materials have some uniquely useful magnetic properties, and optical materials deal with changing the way photons interact with the material.

Computational materials science is a branch of materials science which deals with computer simulations.This contrasts with Experimental materials science, which is the stuff people do in a laboratory. Computational materials science relies on simplifying the material system, applying rules for how the individual units behave, and processing the results. Computer simulations can work for any material and may model anything from small groups of atoms (molecular dynamics) to wave functions (density functional theory) to large macro-structures (finite element method).

Biological materials are materials that integrate with biological systems. These can include:

- Biocompatible materials, which are designed to be chemically neutral in the body. In other words, these materials are implanted in the body for some primary purpose, often structural, and need additional engineering to make sure they don’t poison you.

- Bioactive materials, which do interact with the body, but in a positive way. I’ve already mentioned one of my undergraduate projects to produce bioactive glass. In this case, the glass was supposed to react with internal fluids to create a compound that your body would think was bone. This would cause your body to grow bone directly onto the bioactive implant, avoiding invasive screws.

- Biodegradable materials are designed to dissolve in your body. They can provide structural support while your body heals, and dissolve harmlessly at a rate similar to the rate your body heals. One example of this is BMAS (biodegradable magnesium alloy stent).

- Biomimetic materials are materials which are nature-inspired. The degree to which they depend on biological understanding can vary, and the longer a biomimetic material has been around, the more likely it is to just be considered a “regular material.” For example, a hexagonal honeycomb shape–while originally inspired by honeycombs–has been widespread throughout the engineering world for so long that it is not considered biometric. On the other hand, you may have heard of research to figure out why spider silk is so strong, or why seashells are so tough. Biomimetic materials science is figuring out the reasons for excellent properties in naturally-occurring materials and reproducing them in man-made materials.

There are also “biological” materials that don’t really fit into these categories. For example, stents are made of a shape memory alloy (which is definitely a functional material) but must also be biocompatible. If you were trying to fine-tune the shape memory effect for the human body, I would consider you to be working on biological materials science because of the intended application. Similarly, if you were working on a metallic foam because you wanted the implant to match the strength and density of bone–even though you are dealing with mechanical properties–many people would consider you to be working on a biological material. In many cases, such a project would be a joint effort between the biological division and the structural division of the materials science department.

Energy materials are often paired with Environment materials . . . because it’s easier to secure funding that way? Energy materials mostly means batteries, but it can also mean any material designed for some energy production application. This could mean for the petroleum industry, but in my experience there is a stigma associated with petroleum, so the division is often called “Energy and Environment” and petroleum-related materials will be split up among other departments.

In addition to materials for battery technology (which includes conductors, insulators, energy storage, and even thermal management), energy materials can also mean materials for nuclear reactors (structural, thermal, radiation-resistant), hydro-power generators, wind turbines, solar cells, and especially experimental energy-production methods. My wife worked on ITER (International Thermonuclear Experimental Reactor, which is trying to generate energy by nuclear fusion) for a year. That fusion project involved steel, copper, superconductors, and superalloys. These would all normally belong in the structural materials division, but they would be classified as energy materials in this case because of their application. Materials for the environment are often alternative-energy materials, but that division may work on recycling as well.

Fundamental Concepts

Other pages on this site will cover each of these topics at the same level as a university course. However, I just want to give you a sample platter of the most important concepts. Everyone in materials science needs to learn at least a little about these topics–all materials scientists will use one of these topics daily, but nobody would need a PhD-level understanding of all the basics.

Crystals

Crystals are atoms arranged in repeating units. Most metals and ceramics are crystals, and glass is one of the rare materials which is not crystalline. Polymers are semicrystalline, which means the molecules have some degree of order, but they aren’t perfectly repeating.

Grains

Grains are groups of atoms in one crystallographic direction. Most people think of diamond as a crystal and are incredulous when I tell them that steel is also a crystal. The difference is that diamond (at least the kind you buy for a ring) is a single crystal, which means it has no grains. Every atom in the diamond repeats exactly like every other atom. Most materials are polycrystalline, which means they have many grains. Each grain has atoms all arranged in the same direction, but grains are oriented randomly compared to each other. Grains are also super small, which is why you don’t notice any “crystals” in steel.

Defects

Defects are slight deviations from perfect crystallographic order. The simplest defect is a vacancy (shown below). Among defects of crystal structure you can also find dislocations, grain boundaries, stacking faults, and many others. Since this is a more advanced topic, I will have to explain it in another article.

Bonding

Bonding is how atoms or molecules attach to each other. Understanding this is key to many computational methods, and bonding affects crystal structures and thermodynamically stable phases.

Thermodynamics

Thermodynamics takes a few basic principles and uses them to predict the future. Thermodynamics is used in many fields, but its concepts are incredibly central to materials science. Thermodynamics tells us what phase a material will be in, and how that phase can change (for example, heat ice and it turns to water). Thermodynamics tells us what will happen, but kinetics tells us when it will happen.

Kinetics

Kinetics is the study of moving stuff (usually particles, but it can apply to non-particles like heat as well). One of the main applications of kinetics is diffusion, which is the random mixing of atoms.

Failure

Failure is a broad term that encompasses any time a material loses usefulness. In many cases that means the material has cracked, but it can also include heat degradation, chemical corrosion, or radiation damage. Corrosion alone accounts for more than 3% of the US GDP, so you can see that preventing material failure is a very important job.

What is the Difference Between Materials Engineers and other Engineers?

Materials Science and Engineering shares similarities with chemical engineering, mechanical engineering, civil engineering, electrical engineering, and biomedical engineering; as well as chemistry and physics.

Every one of these disciplines require materials, and most of these need to understand at least one corner of the materials tetrahedron.

| College Major | Major Industries | Median Annual Wage (US 2018) |

| Materials Science & Engineering | Aerospace Scientific Research Architecture & Engineering Services | $99,800 |

| Chemical Engineering | Chemical Manufacturing Scientific Research Architecture & Engineering Services | $104,910 |

| Mechanical Engineering | Machine Manufacturing Scientific Research Architecture & Engineering Services | $87,370 |

| Physics | University Federal Executive Branch Architecture & Engineering Services | $120,950 |

| Biomedical Engineering | Medical Equipment Manufacturing Pharmaceutical Manufacturing Scientific Research | $88,550 |

| Chemistry | Pharmaceutical Manufacturing Scientific Research Architecture & Engineering Services | $76,890 |

All engineers earn a median salary of around $100,000 annually. Physicists (those that can find a job at least) earn more, and chemists earn less (probably because there are a lot more people with chemistry degrees than physics degrees).

With regards to subject matter, materials science and biomedical engineering are the most broad and interdisciplinary. That tends to make them easier majors than more highly focused majors.

As an undergraduate student in materials science, I took more chemistry than the physics majors and more physics than the chemistry majors. As a result, I didn’t need to take the most difficult classes in theoretical physics or organic chemistry (this is not true if you are in graduate school, or if you do research in one of these areas).

Just as materials engineers work in the space between chemistry and physics, biomedical engineers work in the space between biology and chemistry. Biomedical engineering focuses on medical devices, biomaterials, biology, biomechanics prosthesis, tissue engineering, and more.

| College Major | Subject | Difficulty |

| Materials Science & Engineering | Everything about materials (solids) | 6/10 |

| Chemical Engineering | Chemical and industrial processes | 9/10 |

| Mechanical Engineering | Machines Design and Manufacturing | 8/10 |

| Physics | Interactions of forces (nuclear, electromagnetic…) | 10/10 |

| Biomedical Engineering | Connecting biology to engineering | 6/10 |

| Chemistry | Chemical reactions (fluids) | 7/10 |

There is a whole sub-field of materials science that deals with bio-materials, but I’m sure the biomedical engineers prefer to think of that as a subfield of their own discipline. If you are interested in engineering a prosthetic implant, you are probably on the materials scientist side of things. If you are interested in creating the original design or performing clinical trials, you may be on the biomedical side of the team. Either background will allow you to work with biomaterials.

Materials science, chemistry, and chemical engineering all work with fluids. For materials science, the fluid is usually used for an intermediate processing step. Chemical engineers specialize in designing these processing steps, so they need lots of fluid dynamics (that’s why I rated the major as being difficult!).

Chemists tend to work in laboratories in small-scale reactions. Chemistry is usually not an especially difficult STEM major, but because chemists need to take one or two semesters of organic chemistry, I rated them slightly harder than materials science.

In graduate school, materials science most resembles solid-state physics. I have gotten away from this in my research, but my classes “need to be” difficult to prove that grad students can do hard things. Many grad students in the highest-ranked universities focus entirely on the physics aspect of materials science, especially when they build computational models. Based on the physics oriented classes I’ve taken in grad school, I’m giving physics the maximum difficulty score.

Mechanical engineering, which resembles high school physics (classical mechanics) rather than “real” physics, is traditionally considered the major most-similar to materials science.This major deals with balancing forces when designing load-bearing parts.

All mechanical engineers will need to take one or two introductory materials science classes. I can’t verify this, but I have heard that half of mechanical engineering jobs are actually materials science jobs (failure analysis and materials selection), but there are so many more mechanical engineering students that employers are willing to hire mechanical engineers who have taken a couple classes on the subject.

Mechanical engineers will probably need more math than materials scientists, and they may need to learn more computer software, so I’m rating the major as more difficult.

Jobs in Materials Science

One of the most enticing reasons to study materials science is that the field is extremely versatile. Students can find employment in any industry. Even an undergraduate degree in materials science will prepare you to think about new problems. Materials science is not well known, so there is a serious lack of information on the web. We are trying to rectify this, but the fact remains: even in undergraduate courses, you will have homework questions that you can’t find online. You will need to work with others and figure things out on your own.

Additionally, materials science departments typically place high emphasis on undergraduate research. Undergraduate research is the single most important factor for landing an internship or getting accepted into graduate school. Even the course material, since it is so broad, can allow students of materials science to switch fields easily. This field-switching is so common that I could even write an entire article on why so many materials scientists switch fields! The short answer is that materials scientists tend to always want to try new things, and because of their diverse backgrounds, they have that option. Chemistry, and especially and physics undergraduates often get their graduate degree in materials science because the degree is so marketable. Materials scientists can often get jobs advertised for petroleum engineers, nuclear engineers, physicists, chemists, biomedical engineers, and mechanical engineers. I’ve heard of people getting jobs as a lunar rock geologist, trading algorithm writer, and even a furniture artist.

Now that you know that job opportunities for materials scientists are limitless, here are a few of the most common areas that materials scientists work:

- Research and Development is one of the first industries people think materials scientists work. Since the field is so new and so much depends on new discoveries, many of us find lucrative positions in research at private companies, national labs, or universities.

- Materials Selection is the job tasked with choosing which material to make something out of. This involves knowledge of a wide range of materials. Materials scientists with this job often need to make a cost-benefit analysis and work with mechanical engineers to choose the best materials within a budget.

- Corrosion Prevention is one of the most important industries in the world. Almost everything corrodes, and that’s almost always a bad thing. Since materials scientists study thermodynamics, kinetics, and phase transformation, we are uniquely educated to succeed in this industry.

- Failure Analysis, similar to corrosion, is a problem that plagues every industry. A materials scientist can study the failure, determine its cause, and recommend steps to avoid material failure in the future.

- Material Forensics can be quite similar to failure analysis, but it can also include archeological studies. For example, I know some materials scientists who got their hands on some wreckage of the Titanic and determined why it sank. Materials scientists may be consulted in legal affairs–for example, they may be asked to analyze the wreckage from a car accident to determine who was at fault. If you’re lucky, you may even be asked to analyze some historical artifacts!

- Computational work can apply to any industry. Since computing power is ever-increasing and simulation methods are always improving, there is a strong demand for engineers that can use computational methods. An interesting thing about computer simulations is that the skills are largely transferable to entirely separate industries, like the stock market.

- Semiconductors are another huge industry for materials engineers. It’s very difficult to create computer chips–one of my old professors used to say that computer chips are the most perfect objects in the universe. That level of engineering requires serious talent.

To back up my own experience, I have data taken from the US Department of Labor and Statistics for jobs labelled as “materials scientist” and materials engineer” but not “chemist and materials scientist.” The data was collected in May 2018. Also note that while someone with a background in materials science is perfectly suited to prevent corrosion in petroleum companies, their job title will likely not involve the words “materials engineer.”

| Industry | Percent of Materials Scientists and Engineers Working in Industry |

| Architectural, Engineering, and Related Services | 12.61% |

| Aerospace Product and Parts Manufacturing | 9.17% |

| Scientific Research and Development Services | 11.83% |

| Federal Executive Branch (OES Designation) | 3.95% |

| Semiconductor and Other Electronic Component Manufacturing | 5.22% |

Final Thoughts

So, what is materials science? It is the study of what things are made of. We look at existing materials, try to figure out what makes them good, and use that information to make even better materials. We help select the correct material for the correct application. We investigate failed parts and perform forensic analysis. We are the focal point for science to be realized by engineers.